What training is provided to operators for safe and efficient operation of the automatic alcohol wet tissue making machine?

On February 28, 2024 by Javier James With 0 Comments

- Blogging

Operators of an automatic alcohol wet tissue making machine require comprehensive training to ensure safe and efficient operation.

Here are the key components of the training program:

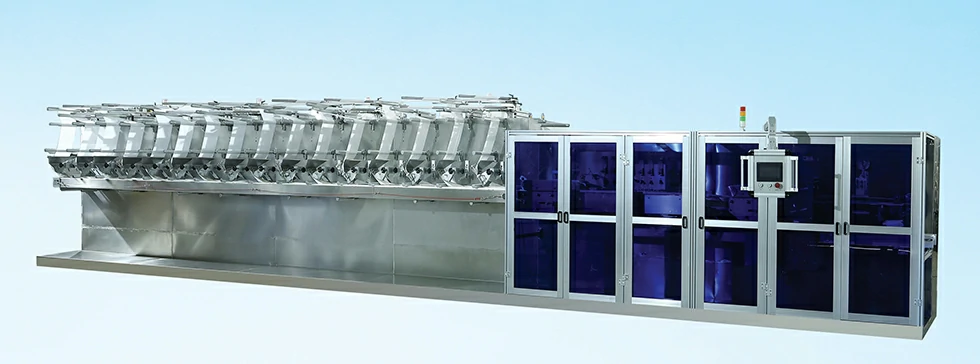

- Machine Familiarization: Operators should receive training on the basic components, functions, and operation of the automatic alcohol wet tissue making machine. This includes understanding the various sections of the machine, such as unwinding, printing, folding, wetting, cutting, and packaging.

- Safety Procedures: Emphasize the importance of safety procedures and protocols to prevent accidents and injuries. Train operators on the use of safety equipment, emergency stop buttons, and proper handling of hazardous materials such as alcohol-based solutions.

- Operating Procedures: Provide detailed instructions on how to set up, operate, and shut down the machine safely and efficiently. This includes loading raw materials, adjusting machine settings, monitoring production processes, and troubleshooting common issues.

- Quality Control: Train operators to perform quality control checks at various stages of the production process to ensure that the finished wet tissues meet quality standards. This includes inspecting for defects, measuring dimensions, and verifying moisture content.

- Maintenance Procedures: Educate operators on routine maintenance tasks such as cleaning, lubrication, and minor repairs. Provide guidance on how to identify signs of wear or damage, perform preventive maintenance, and report any issues to maintenance personnel.

- Troubleshooting: Equip operators with problem-solving skills to identify and resolve common issues that may arise during machine operation. automatic alcohol wet tissue making machine Train them to diagnose mechanical problems, adjust machine settings, and implement corrective actions to minimize downtime.

- Safety Data Sheets (SDS): Provide training on the safe handling and storage of chemicals used in the production process, such as alcohol-based solutions. Ensure that operators understand the information provided in Safety Data Sheets (SDS) and follow proper handling procedures.

- Emergency Response: Train operators on how to respond to emergencies such as equipment malfunctions, chemical spills, or injuries. Provide instruction on evacuation procedures, first aid techniques, and how to contact emergency services if needed.

- Regulatory Compliance: Educate operators on relevant regulations, standards, and guidelines governing the production of wet tissues, including hygiene standards, labeling requirements, and workplace safety regulations.

- Supervised Practice: Allow operators to gain hands-on experience under the supervision of experienced personnel. Provide opportunities for guided practice sessions to reinforce learning and build confidence in operating the machine.

- Refresher Training: Schedule regular refresher training sessions to reinforce key concepts, address any gaps in knowledge, and update operators on changes to procedures or equipment.

- Documentation and Record-Keeping: Train operators to maintain accurate records of production activities, quality control checks, maintenance tasks, and any incidents or issues encountered during operation.

By providing comprehensive training that covers these aspects, operators can safely and efficiently operate an automatic alcohol wet tissue making machine, ensuring consistent product quality, minimizing downtime, and promoting a culture of safety in the workplace.

Comments are Disabled