Posts By Javier James

Laser Cutting vs. Laser Engraving

What is Laser Cutting?

Laser cutting is a process that involves using a focused laser beam to cut through a material. Hence, it is suitable for creating customizable patterns, shapes, and designs on a workpiece. Like any other laser marking process, it is non-contact, i.e., the machine does not directly touch the material. Nevertheless, the laser beam can cut the material by melting, vaporizing, or burning the part.

Laser cutting is suitable for several materials, including metals (e.g., aluminum and brass), plastics (ABS, Polycarbonate), ceramics, wood, and stone.

What is Laser Engraving?

Differences between Laser Cutting and Laser Engraving

Both processes are categorized under the laser marking procedure. This is because they use laser marking machines to generate beams that can vaporize part or all of a product. Although similar, below are some differences between laser cutting and laser engraving:

· Principle of Cutting

Laser cutting involves using a laser beam to cut through the entire thickness of the material by melting, burning, and vaporizing. Most cuts are perfect. Hence, they don’t need a second touch-up. On the other hand, laser engraving involves cutting to the desired depth without cutting through the entire thickness. Therefore, engraved materials only have their surfaces vaporized to the required depths.

· Laser Power

One of the most important disparities in the laser cutting vs. laser engraving process is based on the machines used. Here, the laser power is a definitive parameter. On the one hand, laser cutters are machines with a laser power above 60W. High power is important for cutting, although it depends on the material’s type and thickness. On the other hand, laser engravers have a laser power below 60W.

The difference in laser power also restricts the types of laser machines compatible with the process. For example, most laser cutting machines are fiber or CO2 laser markers. However, laser engravers can include other laser marking machines, such as UV or green lasers.

Keynote: Laser engravers can cut thin sheets of non-metals.

· Lens Focal Length

Another important difference in comparing the two processes is the focus lens used in the laser machines. Laser cutting machines have a lens with a long focal length. Consequently, they deliver smooth cut edges, making them aesthetically pleasing. On the other hand, laser engraving machines have a lens with a short focal length. Consequently, they give an object a finer spot size, improving the engraving quality.

· Cutting Speed

Generally, the laser cutting process is very slow due to the time and energy it takes to completely vaporize a material. However, this depends on the material you are cutting and its dimension. For example, a thin metal will take less time than a thick one, while a thin plastic will take less time than a thin metal. Furthermore, the slow cutting speed ensures that the forefront is smooth and of good quality.

Laser engraving has a higher cutting speed as the process does not involve cutting. Aside from that, it aids efficiency and reduction of contact time. However, cutting at too much speed can lead to low-quality marking.

· Design File Format

Laser cutting machines use vector design files, while engraving machines use vector and raster design files.

The vector design format is applicable in laser workings that require thin lines, and it involves using laser beams to trace the lines and curves of the design vector by vector. Vector design files can be in EPS, AI, or CDR formats.

The raster design format applies to laser working materials such as wood, stamps, and papers. It involves building the design from pixels and engraving it line by line or point by point. Raster files are in JPG or PNG format.

· Use of Assist Gas

Assist gases such as helium and oxygen helps in expelling the molten material seen during the laser cutting process. As a result, they are highly recommended for cutting thick materials. Aside from expelling molten materials, they also cut a smooth finish look.

On the other hand, laser engraving does not require to assist gas because it can create a pop that affects the outlook of the surface finish. However, you can use it when the engraving process produces too much smoke, as the gases prevent the smoke from affecting the marking quality.

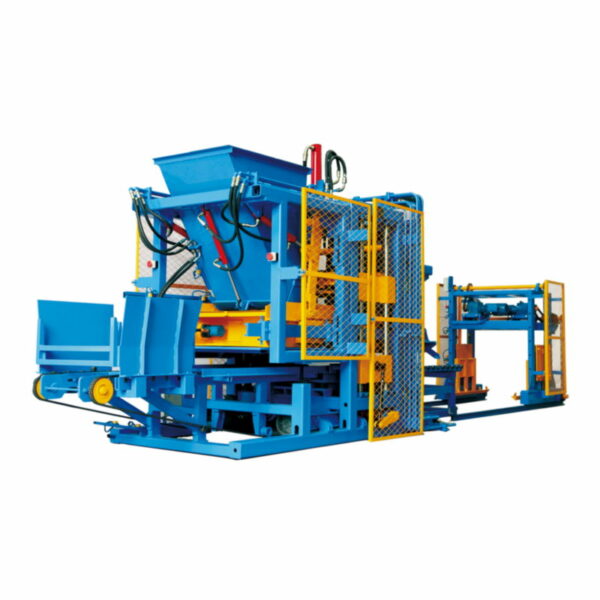

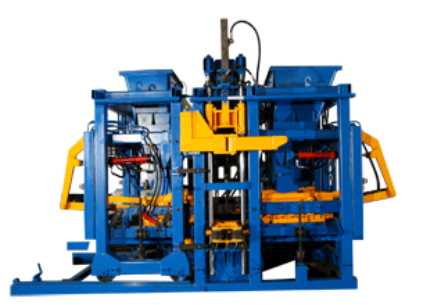

How Do These Machines Produce Blocks?

Paver blocks are made from crusted stone dust, grit between 4 and 10 mm, cement, concrete admixture, and water as raw materials. The paver block making machine manufacturers in india, gujarat, morbi also use various aggregate, that includes sand, crushed stone, slag, and recycled concrete.

Four processes make up the majority of the process: proportioning, mixing, compacting, and drying. A paver block is typically made in a ratio of 1:3:5, which equals 5 parts aggregate to 3 parts sand to 1 part cement. However, depending on your needs, this ratio may change. For the mould to properly fill the material during this operation, strong vibration is also applied. This is a unique characteristic of our device. It’s time to heal the block under the sun after that. The blocks only need a short amount of time to develop outstanding strength.

It’s noteworthy to see that anyone can obtain a time estimate for constructing a paver block. The PLC panel or electrical panel board can be used to determine the entire production. The panel features a feature where the history of each day’s production is displayed, which might be useful for understanding the overall result. This panel also allows you to change our automatic paver block maker into a semi-manual or manual machine. The best machine must produce high-quality results while requiring very little upkeep. We offer the aforementioned paver block manufacturing equipment that can produce a variety of paver block sizes and shapes, including the I-shape, Hexagone, and Zic-zac blocks, among others.

Advantages of Paver Block Making Machine

The building blocks are sufficiently common to produce a natural level of fire protection, a good eco-friendly one, and more. To reap the benefits of these robust blocks, investing in a high-tech hollow block or paver machine is worthwhile. Using manual paver block machine has many advantages, including adaptability, strong construction, consistency, and more. Let’s talk about these block-making machines’ main benefits.

An Effective Thermal Insulation

Thermal insulation, which creates a sort of barrier between the hot and cold object to preserve the machine’s temperature in both situations, is the process of insulating against the transmission of heat.

Customizable

Since paver blocks are a very adaptable material, the paver block machine must be able to produce them in a variety of shapes, sizes, and colours for both indoor and outdoor use. The Block, Hollow Block, and Interlocking Paver Block Machine from the top interlocking block making machine manufacturer features advanced customizability and a control system. These methods make it possible to modify the moulding design as necessary.

Uniformity

The production of paver blocks in the same quality and standard is aided by a clever interlocking paver block machine. The paver block production machine must be kept in good working order to maintain the block’s quality. The paver block manufacturing method affects the block’s homogeneity. A fully automatic conrete paver block machine Supplier creates similar standard blocks over the same amount of time.

Quick and accurate

Due to its hydraulic pressure system, which enables it to produce precise, high-quality blocks that outperform those made by any human equipment or method, quick and accurate paver block making machines are quite popular today. The machine’s sophisticated feeding system aids in boosting production as quickly as possible.

Cost reduction

The best strategy to make the most money is to cut costs overall and manufacture the most blocks possible in the shortest amount of time. The maker of block machines creates automatic and manual equipment to make your job easier and maybe save money on labour and electricity.

How durable are the blocks produced by block production machine?

The durability of blocks produced by block production machines can vary depending on several factors, including the quality of materials used, the manufacturing process, the design of the blocks, and environmental conditions. Generally, blocks produced by block production machines are designed to be durable and able to withstand the stresses and conditions they will encounter in their intended applications.

Here are some factors that contribute to the durability of blocks:

- Material Quality: The quality of the materials used in block production significantly affects the durability of the blocks. High-quality cement, aggregates, and additives should be used to ensure the blocks have adequate strength, resistance to weathering, and durability over time.

- Mix Design: The mix design of the concrete used to produce blocks plays a crucial role in determining their strength, durability, and other properties. Proper proportions of cement, aggregates, water, and additives should be used to achieve the desired characteristics of the blocks.

- Compaction: Proper compaction of the concrete mix within the block production machine is essential for ensuring the density and strength of the blocks. Adequate compaction helps eliminate voids and ensures uniform distribution of materials throughout the block, enhancing its durability.

- Curing Process: The curing process after block production is critical for achieving optimal strength and durability. Blocks should be properly cured under controlled conditions, such as adequate temperature and humidity, to promote hydration and development of strength.

- Block Design: The design of the blocks produced by block production machines can influence their durability. Blocks with reinforced cores, block production machine interlocking features, or special surface treatments may offer enhanced durability and resistance to cracking, weathering, and other forms of damage.

- Quality Control: Strict quality control measures should be implemented throughout the production process to ensure the consistency and uniformity of the blocks. Regular testing of raw materials, concrete mixtures, and finished blocks can help identify and address any issues that may affect durability.

- Environmental Factors: Environmental conditions, such as exposure to freeze-thaw cycles, moisture, sunlight, and chemical exposure, can impact the durability of blocks. Proper design, material selection, and installation techniques should be used to mitigate the effects of environmental factors on block performance.

Overall, blocks produced by block production machines can be highly durable when manufactured using high-quality materials, proper mix design, compaction, curing, and quality control measures. However, it’s essential to consider the specific requirements and conditions of the intended application to ensure the blocks meet the desired level of durability and performance over time. Regular maintenance and proper installation practices can also contribute to maximizing the longevity and durability of blocks in various construction applications.

How efficient is a block making machine in terms of production rate?

The efficiency of a block making machine in terms of production rate can vary depending on several factors, including the type of machine, its capacity, the size and complexity of the blocks being produced, and the operating conditions.

Here are some key factors that influence the production rate and efficiency of block making machines:

- Machine Type: There are various types of block making machines, including manual, semi-automatic, and fully automatic machines. Fully automatic machines generally have higher production rates compared to manual or semi-automatic machines due to their automated processes.

- Capacity: The capacity of a block making machine refers to the number of blocks it can produce in a given time period, typically measured in blocks per hour (BPH) or blocks per day. Machines with higher capacities can produce more blocks in the same amount of time, thus increasing production rates.

- Block Size and Complexity: The size, shape, and complexity of the blocks being produced can impact production rates. Producing larger or more intricate blocks may require additional time and resources compared to standard-sized blocks.

- Cycle Time: The cycle time of the machine, which includes the time required for molding, curing, and demolding the blocks, directly affects production rates. Machines with shorter cycle times can produce blocks more quickly, block making machine for sale in usa leading to higher efficiency.

- Operator Skill and Experience: The skill and experience of the machine operator can also influence production rates. A well-trained and experienced operator can optimize machine settings, troubleshoot issues quickly, and maintain consistent production flow, leading to higher efficiency.

- Maintenance and Downtime: Regular maintenance and minimal downtime are crucial for maintaining high production rates. Machines that require frequent maintenance or experience frequent breakdowns may have lower overall efficiency due to interruptions in production.

- Raw Material Quality and Availability: The quality and availability of raw materials, such as cement, aggregates, and additives, can impact production rates. Adequate supply of quality materials is essential for uninterrupted operation and consistent block quality.

- Automation and Control Systems: Fully automatic block making machines often incorporate advanced automation and control systems, which can optimize production processes, minimize human error, and increase efficiency compared to manual or semi-automatic machines.

Overall, the efficiency of a block making machine in terms of production rate depends on a combination of these factors. Manufacturers and operators should consider these factors carefully when selecting, operating, and maintaining block making machines to maximize productivity and efficiency in block production.

How does the maintenance schedule for block making machines look like?

The maintenance schedule for block making machines typically involves regular inspection, cleaning, lubrication, and repair tasks to ensure optimal performance, prevent breakdowns, and prolong the machine’s lifespan. While specific maintenance requirements may vary depending on the type and model of the machine, as well as the manufacturer’s recommendations

Here is a general outline of a maintenance schedule for block making machines:

- Daily Maintenance:

- Check all moving parts and components for signs of wear or damage, such as belts, chains, bearings, and hydraulic components.

- Clean the machine thoroughly, removing any debris, concrete block maker dust, or buildup from the surfaces, molds, and conveyor systems.

- Lubricate moving parts and components as needed, following the manufacturer’s recommendations for the type and quantity of lubricant to use.

- Check hydraulic fluid levels and top up if necessary.

- Verify that safety features and emergency stop mechanisms are functioning correctly.

- Weekly Maintenance:

- Inspect electrical wiring and connections for signs of damage or loose connections, and tighten or repair as needed.

- Check and adjust tension on belts and chains, ensuring proper alignment and tension for smooth operation.

- Test the machine’s controls and sensors to ensure proper functioning.

- Inspect molds and replace or repair any damaged or worn-out mold components.

- Monthly Maintenance:

- Perform a more detailed inspection of hydraulic systems, including hoses, pumps, valves, and cylinders, checking for leaks, wear, or damage.

- Clean and inspect air filters, fuel filters, and oil filters, replacing them if necessary.

- Check for any abnormal vibrations, noises, or other signs of mechanical problems, and investigate and address any issues promptly.

- Grease or lubricate all bearings, shafts, and other moving parts as recommended by the manufacturer.

- Quarterly Maintenance:

- Conduct a thorough inspection of the machine’s structural components, including frames, supports, and welds, checking for cracks, corrosion, or other structural issues.

- Test and calibrate the machine’s sensors, gauges, and control systems to ensure accuracy and reliability.

- Inspect and clean the electrical panels, block maker machine switches, and contactors, checking for signs of overheating or damage.

- Perform any necessary adjustments or alignments to ensure proper operation and alignment of all components.

- Annual Maintenance:

- Schedule a comprehensive maintenance and service check by qualified technicians or service professionals.

- Disassemble and inspect critical components, such as the gearbox, motor, and hydraulic system, for wear, damage, or corrosion, and repair or replace as needed.

- Conduct a thorough cleaning and lubrication of all components and systems.

- Review and update maintenance records, including any repairs or replacements performed during the year.

In addition to these scheduled maintenance tasks, it’s essential to address any issues or abnormalities promptly and to follow the manufacturer’s specific maintenance recommendations outlined in the machine’s operation manual. Regular maintenance is crucial for ensuring the safe and efficient operation of block making machines and for maximizing their lifespan and productivity.

What are the factors that affect the lifespan of molds and wear parts used in a cement blocks making machine?

The lifespan of molds and wear parts used in a cement block making machine can be influenced by various factors:

- Material Quality: The quality of materials used in manufacturing molds and wear parts is crucial for their lifespan. High-quality materials with excellent wear resistance, hardness, and toughness, such as hardened steel or special alloys, can withstand the abrasive forces and stresses encountered during block production, leading to longer-lasting molds and wear parts.

- Design and Engineering: The design and engineering of molds and wear parts play a significant role in their longevity. Well-designed molds with proper reinforcement, optimized geometry, and effective cooling channels can withstand the rigors of block production and minimize wear and fatigue. Similarly, wear parts designed with adequate thickness, strength, and reinforcement can resist premature failure and extend their service life.

- Production Volume: The volume of blocks produced and the frequency of machine operation can impact the wear and tear experienced by molds and wear parts. High-volume production or continuous operation can accelerate wear and lead to faster deterioration of molds and wear parts compared to low-volume production or intermittent operation. Proper maintenance and replacement schedules should be implemented based on production volume to ensure optimal performance and longevity of molds and wear parts.

- Material Properties: The properties of the materials being processed, such as aggregates, cement, additives, and admixtures, can affect the wear characteristics of molds and wear parts. Abrasive materials, irregular particle shapes, or high-density aggregates can accelerate wear and increase the likelihood of damage to molds and wear parts. Adjusting the composition or properties of the raw materials may help mitigate wear and prolong the lifespan of molds and wear parts.

- Operating Conditions: The operating conditions of the block making machine, including factors such as temperature, humidity, vibration, and lubrication, can influence the wear rate of molds and wear parts. Extreme operating conditions, such as high temperatures or excessive vibration, can accelerate wear and fatigue, leading to premature failure of molds and wear parts. Proper maintenance, lubrication, and environmental controls are essential for minimizing wear and maximizing the lifespan of molds and wear parts.

- Maintenance Practices: Regular maintenance and proper care are essential for prolonging the lifespan of molds and wear parts. Routine inspection, cleaning, lubrication, and adjustment of molds and wear parts help prevent premature wear, corrosion, and damage. Timely replacement of worn or damaged components is crucial to avoid production downtime and ensure consistent block quality.

By considering these factors and implementing appropriate measures, manufacturers can maximize the lifespan of molds and wear parts used in cement block making machines, leading to improved productivity, efficiency, and cost-effectiveness.

How does the speed and precision of a blocks maker machine affect the quality of the produced blocks?

The speed and precision of a block making machine play crucial roles in determining the quality of the produced blocks:

- Speed: The speed of a block making machine directly influences the production rate and efficiency. Higher speeds allow for more blocks to be produced within a given time frame, which can be advantageous for meeting production demands and deadlines. However, it’s essential to maintain a balance between speed and other factors to ensure the quality of the blocks is not compromised. Excessive speed may lead to issues such as insufficient compaction, uneven curing, or mold wear, resulting in lower-quality blocks.

- Precision: Precision in a block making machine refers to its ability to consistently produce blocks with accurate dimensions, shapes, and surface finishes. Precise control over factors such as material batching, mold alignment, vibration intensity, and curing conditions is essential for achieving uniform block quality. Even minor deviations in these parameters can result in variations in block dimensions, density, strength, and appearance. A high level of precision ensures that each block meets specified standards and performs reliably in its intended application.

- Quality Consistency: The speed and precision of a block making machine are interconnected and directly influence the consistency of block quality. A machine that operates at a consistent speed while maintaining precise control over all aspects of the production process will produce blocks with consistent properties and characteristics. blocks maker machine Consistency in block quality is crucial for ensuring uniformity in construction projects, where blocks with varying dimensions or strengths can lead to structural issues or aesthetic inconsistencies.

- Durability and Structural Integrity: Blocks produced by a block making machine with high speed and precision are more likely to exhibit superior durability and structural integrity. Uniform compaction, accurate dimensions, and consistent material distribution contribute to blocks with higher compressive strength, reduced porosity, and better resistance to environmental factors such as weathering and freeze-thaw cycles. These attributes are essential for ensuring the long-term performance and stability of structures built with the blocks.

- Customer Satisfaction: The speed and precision of a block making machine ultimately impact customer satisfaction by influencing the quality, reliability, and efficiency of block production. Customers expect blocks that meet specified standards, perform as intended, and are delivered in a timely manner. A machine capable of producing high-quality blocks quickly and consistently helps meet these expectations, leading to satisfied customers and repeat business.

In summary, the speed and precision of a block making machine are critical factors that directly affect the quality of the produced blocks. Balancing speed with precision is essential to ensure efficient production without compromising block quality, durability, or customer satisfaction.

How does the energy efficiency of a block making machine affect its performance?

The energy efficiency of a block making machine can significantly impact its overall performance in several ways:

- Operational Costs: Energy consumption is a significant operating cost for block making machines. A more energy-efficient machine will consume less power during operation, resulting in lower energy bills and reduced operating expenses. This can lead to improved profitability and cost-effectiveness for the manufacturer or operator.

- Production Efficiency: Energy-efficient block making machines often utilize advanced technologies and design features to optimize energy usage while maintaining high production rates. By minimizing energy waste and maximizing energy utilization, these machines can operate more efficiently and consistently, leading to higher productivity and throughput.

- Environmental Impact: Energy-efficient block making machines consume less electricity or fuel, resulting in reduced greenhouse gas emissions and environmental impact. This aligns with sustainability goals and regulatory requirements aimed at reducing carbon emissions and mitigating climate change. block making machine china Additionally, energy-efficient machines may qualify for environmental certifications or incentives, further enhancing their appeal to environmentally conscious customers.

- Reliability and Durability: Energy-efficient block making machines may incorporate features such as improved insulation, optimized heating elements, and efficient motor systems. These enhancements can contribute to the machine’s overall reliability and durability by reducing thermal stress, minimizing wear and tear on components, and extending service life. A more robust and dependable machine can enhance overall performance by reducing downtime and maintenance requirements.

- Market Competitiveness: In today’s competitive market, energy efficiency has become a significant differentiator for manufacturers of block making machines. Energy-efficient machines are often perceived as more advanced, technologically sophisticated, and environmentally responsible, enhancing their market appeal and competitiveness. Customers may prioritize energy efficiency when selecting a block making machine, giving an edge to manufacturers that offer energy-efficient solutions.

Overall, the energy efficiency of a block making machine is closely intertwined with its performance, operational costs, environmental impact, and market competitiveness. By prioritizing energy efficiency in machine design, block making machine for sale manufacturers can deliver products that offer improved productivity, sustainability, and value to their customers.

What are the quality control measures implemented in a block making machine to ensure consistent block quality?

Quality control measures are essential in block making machines to ensure consistent block quality. Here are some common measures implemented in these machines:

- Raw Material Testing: Before production begins, raw materials such as aggregates, cement, and additives are tested for quality and consistency. This ensures that only materials meeting specified standards are used in block production.

- Batching Accuracy: Block making machines often feature precise batching systems that accurately measure and mix raw materials in the correct proportions. Automated batching systems reduce human error and ensure consistent block quality by maintaining precise material ratios.

- Vibration Control: Vibration is a critical aspect of block making machines as it helps compact the mixture and remove air voids, ensuring uniform block density and strength. Quality control measures may include systems to monitor and regulate vibration frequency, intensity, and duration to achieve consistent compaction and block quality.

- Mold Alignment and Dimension Control: Proper alignment and dimension control of molds are crucial for producing blocks with uniform shape and size. Block making machines may incorporate mechanisms to ensure precise mold alignment and dimensional accuracy, such as adjustable mold guides and sensors for real-time monitoring.

- Curing and Drying Control: Consistent curing and drying processes are essential for achieving optimal block strength and durability. China block machines Block making machines may feature controlled curing chambers or drying systems with precise temperature, humidity, and airflow regulation to ensure uniform curing and drying conditions for all blocks.

- Quality Inspection and Testing: Automated inspection systems may be integrated into block making machines to inspect finished blocks for defects such as cracks, voids, or dimensional inconsistencies. These systems use sensors, cameras, or other detection methods to identify and reject defective blocks, ensuring only high-quality blocks are delivered to customers.

- Process Monitoring and Data Logging: Block making machines may include monitoring and data logging capabilities to track process parameters such as material flow rates, vibration settings, curing temperatures, and production rates. This data can be analyzed to identify trends, optimize machine settings, and address any deviations from quality standards.

- Regular Maintenance and Calibration: Proper maintenance and calibration of block making machines are essential for ensuring consistent performance and block quality over time. Regular inspections, cleaning, lubrication, and calibration of machine components help prevent wear and tear, minimize downtime, and maintain optimal operation.

By implementing these quality control measures, block making machines can consistently produce high-quality blocks that meet industry standards and customer requirements. This helps build trust and confidence in the reliability and performance of the machines, leading to satisfied customers and long-term success for manufacturers.

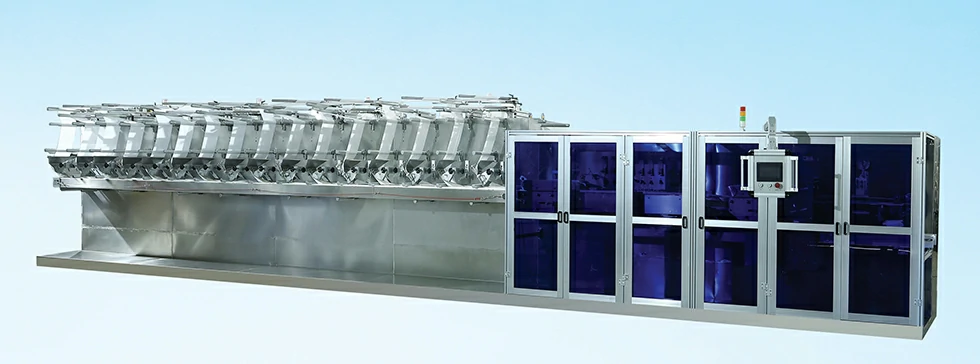

How do you monitor production output and adjust disposable towel for wet wipes machine settings accordingly?

Monitoring production output and adjusting disposable towel for wet wipes machine settings accordingly involves several steps to optimize efficiency and maintain quality. Here’s a guide:

- Establish Baseline Metrics: Begin by establishing baseline metrics for production output, such as the number of wet wipes produced per hour or shift, production speed, defect rates, and material usage.

- Real-Time Monitoring: Implement real-time monitoring systems to track production output continuously. This can include sensors, counters, or software programs that collect data on production rates, downtime, and quality metrics.

- Collect Data: Gather data on production performance, including production volume, cycle times, downtime events, and quality control checks. Use this data to identify trends, patterns, and areas for improvement.

- Monitor Quality: Monitor the quality of the wet wipes produced, including factors such as moisture content, thickness, seal integrity, and packaging appearance. Conduct regular quality control checks to ensure that the product meets specifications.

- Identify Bottlenecks: Identify any bottlenecks or inefficiencies in the production process that may be limiting output or affecting quality. disposable towel for wet wipes machine This could include equipment malfunctions, material shortages, or operator errors.

- Analyze Performance: Analyze production data to identify factors that may be impacting production output or quality. Look for correlations between machine settings, material specifications, and production performance.

- Adjust Machine Settings: Based on the analysis of production data and quality metrics, adjust machine settings as needed to optimize performance. This may include parameters such as machine speed, tension settings, temperature controls, and material feed rates.

- Test and Validate Changes: Before implementing significant changes to machine settings, conduct tests to validate their impact on production output and product quality. Monitor the results closely and make adjustments as necessary.

- Train Operators: Ensure that operators are trained to monitor production output and recognize signs of inefficiency or quality issues. Provide training on how to adjust machine settings and troubleshoot common problems to minimize downtime.

- Continuous Improvement: Implement a culture of continuous improvement, where production processes are regularly reviewed, and adjustments are made based on performance data. Encourage feedback from operators and stakeholders to identify opportunities for optimization.

- Document Changes: Keep records of any changes made to machine settings, production processes, or quality control procedures. Document the results of these changes, including any improvements in production output or product quality.

- Regular Review and Adjustment: Schedule regular reviews of production performance and adjust machine settings accordingly. Monitor the impact of these adjustments over time and make further refinements as needed to maintain optimal production output and quality.

By monitoring production output and adjusting disposable towel for wet wipes machine settings accordingly, manufacturers can optimize efficiency, minimize downtime, and ensure consistent product quality. Regular monitoring, analysis, and adjustment are essential for achieving continuous improvement in production processes.

What training is provided to operators for safe and efficient operation of the automatic alcohol wet tissue making machine?

Operators of an automatic alcohol wet tissue making machine require comprehensive training to ensure safe and efficient operation.

Here are the key components of the training program:

- Machine Familiarization: Operators should receive training on the basic components, functions, and operation of the automatic alcohol wet tissue making machine. This includes understanding the various sections of the machine, such as unwinding, printing, folding, wetting, cutting, and packaging.

- Safety Procedures: Emphasize the importance of safety procedures and protocols to prevent accidents and injuries. Train operators on the use of safety equipment, emergency stop buttons, and proper handling of hazardous materials such as alcohol-based solutions.

- Operating Procedures: Provide detailed instructions on how to set up, operate, and shut down the machine safely and efficiently. This includes loading raw materials, adjusting machine settings, monitoring production processes, and troubleshooting common issues.

- Quality Control: Train operators to perform quality control checks at various stages of the production process to ensure that the finished wet tissues meet quality standards. This includes inspecting for defects, measuring dimensions, and verifying moisture content.

- Maintenance Procedures: Educate operators on routine maintenance tasks such as cleaning, lubrication, and minor repairs. Provide guidance on how to identify signs of wear or damage, perform preventive maintenance, and report any issues to maintenance personnel.

- Troubleshooting: Equip operators with problem-solving skills to identify and resolve common issues that may arise during machine operation. automatic alcohol wet tissue making machine Train them to diagnose mechanical problems, adjust machine settings, and implement corrective actions to minimize downtime.

- Safety Data Sheets (SDS): Provide training on the safe handling and storage of chemicals used in the production process, such as alcohol-based solutions. Ensure that operators understand the information provided in Safety Data Sheets (SDS) and follow proper handling procedures.

- Emergency Response: Train operators on how to respond to emergencies such as equipment malfunctions, chemical spills, or injuries. Provide instruction on evacuation procedures, first aid techniques, and how to contact emergency services if needed.

- Regulatory Compliance: Educate operators on relevant regulations, standards, and guidelines governing the production of wet tissues, including hygiene standards, labeling requirements, and workplace safety regulations.

- Supervised Practice: Allow operators to gain hands-on experience under the supervision of experienced personnel. Provide opportunities for guided practice sessions to reinforce learning and build confidence in operating the machine.

- Refresher Training: Schedule regular refresher training sessions to reinforce key concepts, address any gaps in knowledge, and update operators on changes to procedures or equipment.

- Documentation and Record-Keeping: Train operators to maintain accurate records of production activities, quality control checks, maintenance tasks, and any incidents or issues encountered during operation.

By providing comprehensive training that covers these aspects, operators can safely and efficiently operate an automatic alcohol wet tissue making machine, ensuring consistent product quality, minimizing downtime, and promoting a culture of safety in the workplace.

How does a rack end car interact with other suspension components?

A rack end, also known as a tie rod end, interacts with other suspension components in a coordinated manner to ensure precise steering control, optimal wheel alignment, and effective suspension performance.

Here’s how a rack end interacts with various suspension components:

- Steering Rack: The rack end is connected to the steering rack via the inner tie rod end. Together, they form part of the steering linkage system that translates steering inputs from the driver into lateral movement of the wheels. The rack end’s connection to the steering rack allows it to transmit steering forces and maintain proper alignment of the front wheels.

- Steering Knuckle: The outer tie rod end of the rack end is connected to the steering knuckle, which is attached to the wheel hub and houses the wheel bearings. The tie rod end’s connection to the steering knuckle allows it to articulate and pivot as the wheels turn, enabling precise steering control and alignment adjustment.

- Control Arms: Control arms are suspension components that connect the steering knuckle to the vehicle’s chassis or subframe. While the rack end itself is not directly connected to the control arms, it indirectly influences their operation by helping to maintain proper wheel alignment. Proper alignment facilitated by the rack end ensures that the control arms function effectively in supporting the weight of the vehicle and transmitting forces between the wheels and the chassis.

- Ball Joints: Ball joints are pivotal connections that allow for articulation and movement between suspension components. rack end car factory While the rack end is not directly connected to ball joints, it interacts with them indirectly through its connection to the steering knuckle. Proper alignment and steering control provided by the rack end ensure that the ball joints operate smoothly and effectively, contributing to stable and responsive suspension performance.

- Tie Rods: In addition to the rack end, tie rods include inner tie rod ends that connect to the steering rack and outer tie rod ends that connect to the steering knuckle. Together, they form the tie rod assembly, which is responsible for maintaining proper wheel alignment and transmitting steering forces. The rack end interacts with other tie rod components to ensure consistent alignment and steering control across the front wheels.

- Struts or Shock Absorbers: Struts or shock absorbers are suspension components that dampen shocks and vibrations from the road surface, providing a smooth and controlled ride. While the rack end is not directly connected to struts or shock absorbers, it indirectly influences their operation by helping to maintain proper wheel alignment and steering control. Consistent alignment and steering provided by the rack end contribute to stable and predictable suspension performance, enhancing ride comfort and handling.

Overall, a rack end interacts with other suspension components to ensure precise steering control, optimal wheel alignment, and effective suspension performance. Its connection to the steering rack and steering knuckle, along with its influence on wheel alignment and steering responsiveness, allows the rack end to coordinate with other suspension components to provide stable, responsive, and comfortable driving characteristics.